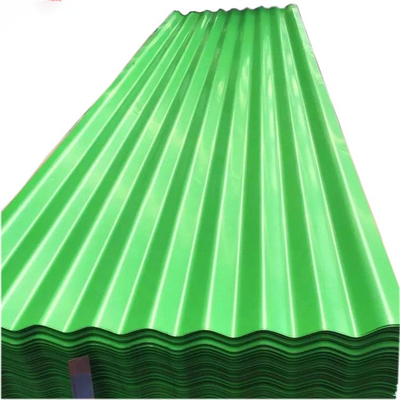

Zinc Painted Surface Roofing Sheet Factory Colorful Metal Ppgi Corrugated Steel Plate

|

Corrugated roof sheets (also known as roof cladding) has been installed on buildings for many years and, due to its very easy installation process and excellent protective qualities, it still proves incredibly popular today.we manufacture and supply full prime steel galvanised corrugated roof sheets to contractors, businesses and the domestic sector. The color-coated coil is a product made of galvanized sheet as the substrate, after surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are applied on the surface, and then baked and cured. It is also named after the color steel coils coated with organic coatings of various colors, referred to as color coated coils |

Specfications

| Product Name | Roofing Steel Sheet Material Plate Q235B Corrugated Steel Roofing Sheet |

| Thickness | 0.13-1.5mm |

| Material | GI/PPGI steel coil prepainted galvanized steel coil |

| Surface treatment | Zinc coated, color coated |

| Zinc coating | 40-275gram/m2 |

| Width | Generally 750mm/ 820mm/ 840mm/ 850mm/ 900mm/ 910mm/ 1050mm/ 1250mm |

| Length | Any length, according to the transportation, usually less than 12m |

| Color |

Standard color: blue, white, red Special color: according to RAL colors |

| Characteristics |

1.weather proof 2. .Anti rust 3. Fire proof 4. Heating insulation 5.Long life span: more than 20 years |

| Packing | Plastic film + wooden pallet or as your request |

| Application |

Building material Container material |

Chemical Composition

| Specification | Grade | Chemical Composition(wt%) | ||||||

| C | Mn | Ni | Cr | Mo | Ti | |||

| ASTMJIS | 316L/022Cr17Ni12Mo2 | ≤0.03 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | - | |

| JIS | SUS316L | ≤0.03 | ≤2.0 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | - | |

| ASTMJIS | 316Ti/SUS 316Ti | ≤0.08 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 5*(C+N)-0.7 | |

Properties

| Spec | Grade | Mechanical Property | Physical Property | ||||

|

Y.S (N/MM2) |

T.S (N/MM2) |

EL (%) |

HRB |

Specific Heat (J/g℃) |

Modulus of Elasticity (KN/mm2) | ||

| ASTM/GB | 316L/022Cr17Ni12Mo2 | ≥170 | ≥485 | ≥40 | ≤95 | 0.5 | 193 |

| JIS | SUS316L | ≥175 | ≥480 | ≥40 | ≤90 | 193 | |

| ASTM | 316Ti | ≥205 | ≥515 | ≥40 | ≤95 | 0.5 | 200 |

![]()

![]()

![]()

![]()

![]()

![]()

Applications:316L: Widely used in corrosion-susceptible environment and some mechanical components those are difficult to make heat treatment after forming in more corrosive environment.

316Ti: Mainly used for industrial components.

|

![]()