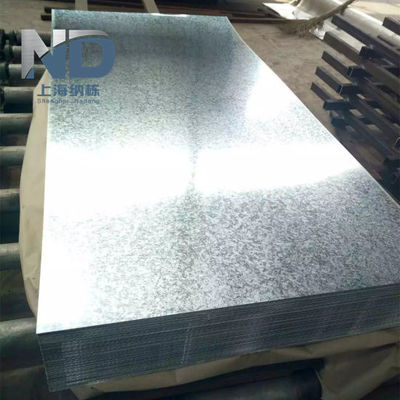

Building Material 0.35mm Hot Dip Galvanized Steel Plate Zinc Coated Steel Sheet

|

After a series of processing services, such as Bending, Decolling, Cutting, Punching, gi coil can be processed into galvanized steel roofing sheet(steel tiles), corrugated steel sheet. And, with the color-coated process, it can be painted with different color and pattern, to be ppgl steel coil,galvanized roofing sheet, gavalume roofing sheet, corrugated galvanized roofing sheet,color steel roof sheet and all this kind of construction materials.

|

Product Description :

| Product Name | Galvanized Steel Sheet | |||

| Length | 1-12m or as required | |||

| Width | 600mm-1250mmor as required | |||

| Thickness | 0.4mm-320mm or as required | |||

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. | |||

| Technique | Cold rolled,hot rolled | |||

| Surface Treatment | Clean, blasting and painting according to customer requirement | |||

| Thickness tolerance | ±0.15mm | |||

| Material | DX51D,Z275,G90,G550,A36,SGCC,SG,DX52D,DX53D Q345,Q345A,Q345B,Q345C,Q345D,Q345E,Q235B HC340LA,HC380LA,HC420LA B340LA,B410LA 15CRMO,12Cr1MoV,20CR,40CR,65MN A709GR50 |

|||

| Coatings | Top Coats :5 micron primer + 20 micron colour Back Coat: 5 micron primer – 7 micron primer | |||

| MOQ | 1tons.We also can accept sample order. | |||

| Shipment time | Within 2-15 workdays after receiving deposit or L/C | |||

| Export packing |

Waterproof paper, and steel strip packed. |

|||

Chemical Composition

| Specification | Grade | Chemical Composition(wt%) | ||||||

| C | Mn | Ni | Cr | Mo | Ti | |||

| ASTMJIS | 316L/022Cr17Ni12Mo2 | ≤0.03 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | - | |

| JIS | SUS316L | ≤0.03 | ≤2.0 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | - | |

| ASTMJIS | 316Ti/SUS 316Ti | ≤0.08 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 5*(C+N)-0.7 | |

Properties

| Spec | Grade | Mechanical Property | Physical Property | ||||

|

Y.S (N/MM2) |

T.S (N/MM2) |

EL (%) |

HRB |

Specific Heat (J/g℃) |

Modulus of Elasticity (KN/mm2) | ||

| ASTM/GB | 316L/022Cr17Ni12Mo2 | ≥170 | ≥485 | ≥40 | ≤95 | 0.5 | 193 |

| JIS | SUS316L | ≥175 | ≥480 | ≥40 | ≤90 | 193 | |

| ASTM | 316Ti | ≥205 | ≥515 | ≥40 | ≤95 | 0.5 | 200 |

![]()

![]()

![]()

Applications:316L: Widely used in corrosion-susceptible environment and some mechanical components those are difficult to make heat treatment after forming in more corrosive environment.

316Ti: Mainly used for industrial components.

|

![]()

![]()