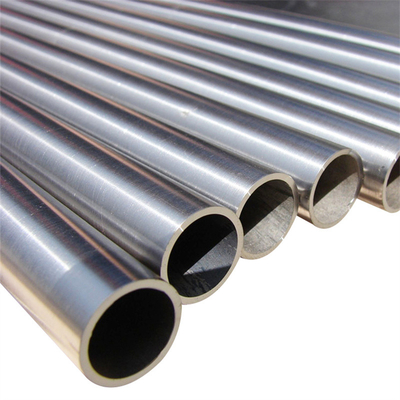

Custom Size Seamless 316 Stainless Steel Tube For Industry Machinery

| We supplie both seamless and welded 316/316L stainless steel Tube. When your application requires a high amount of corrosion resistance, 316/316L Stainless Steel is the right material for your company. The main difference between this grade of stainless steel and 304/304L stainless steel is that 316/316L stainless steel had molybdenum. The addition of this element makes 316 stainless steel able to remain durable in harsh, corrosive environments. |

Specfications

|

Product Name

|

Stainless Steel Pipe/Tube

|

|||

|

Technology

|

Hot Rolled Industrial Stainless Steel Tube

Cold Rolled Decorative Stainless Steel Pipe |

|||

|

Material

|

201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized

|

|||

|

Thickness

|

0.4-50 mm

|

|||

|

Length

|

1-12 m

|

|||

|

Outer Diameter(OD)

|

10-2000mm

|

|||

|

Standard

|

ASTM, JIS, GB, AISI, DIN, BS,EN

|

|||

|

Certifications

|

ISO 9001 BV SGS

|

|||

|

Packing

|

Industry standard packaging or according to client's requirement

|

|||

|

Brand

|

TISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO,HXSCO,

Chengde,Yongjin,Tsingshan,Shouyang,HW |

|||

|

Payment terms

|

30%T/T in advance, the balance against the B/L copy

|

|||

|

Delivery time

|

Fast delievery in 7 days,up to order quantity

|

|||

|

Warehose Stcok

|

5000 tons per month

|

|||

Chemical Composition

| Specification | Grade | Chemical Composition(wt%) | ||||||

| C | Mn | Ni | Cr | Mo | Ti | |||

| ASTMJIS | 316L/022Cr17Ni12Mo2 | ≤0.03 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | - | |

| JIS | SUS316L | ≤0.03 | ≤2.0 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | - | |

| ASTMJIS | 316Ti/SUS 316Ti | ≤0.08 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 5*(C+N)-0.7 | |

Properties

| Spec | Grade | Mechanical Property | Physical Property | ||||

|

Y.S (N/MM2) |

T.S (N/MM2) |

EL (%) |

HRB |

Specific Heat (J/g℃) |

Modulus of Elasticity (KN/mm2) | ||

| ASTM/GB | 316L/022Cr17Ni12Mo2 | ≥170 | ≥485 | ≥40 | ≤95 | 0.5 | 193 |

| JIS | SUS316L | ≥175 | ≥480 | ≥40 | ≤90 | 193 | |

| ASTM | 316Ti | ≥205 | ≥515 | ≥40 | ≤95 | 0.5 | 200 |

![]()

![]()

![]()

![]()

|

316L: Widely used in corrosion-susceptible environment and some mechanical components those are difficult to make heat treatment after forming in more corrosive environment.

316Ti: Mainly used for industrial components.

|

![]()

![]()